Back in 2014, when Diann and I anchored our way down the ICW to Miami, my legs and back worked well for retrieving our 35 pound Delta anchor. The process was simple- hand-over-hand the 5/8 inch nylon rode was retrieved (as Diann motored slowly forward); then the twenty feet of 3/8” chain was pulled up. YachtaFun’s cleat did the work of breaking the anchor free as the boat’s momentum tugged on the anchor. Lastly, my legs did the heavy lifting as the anchor broke out of the bottom. That was then.

Last summer we switched from the rode / chain combo. Now we have 100 feet of G-43 5/16” chain (with an additional 120 feet of 5/8” rode). No anchoring was needed last year, so it was this spring that I did a test of my ability to retrieve the anchor/chain combo.

By attaching a line to the tripping ring on the anchor’s crown, I was able to guide the anchor to drop at the edge of the dock’s walkway. I then dropped the rest of the 100 feet of chain in a pile on the bottom- which was about 11 feet down.

Hand over hand, I pulled up the chain with minor effort- until the anchor began to drag across the muddy bottom. My legs and back were not able to do the work they had eagerly done three years earlier. Well, it was time for a windlass.

Lofrans makes a manually operated version called the Royal. It weighs about 20 pounds which beats the heavier electrically operated versions. Since I can do the chain retrieval by hand, and break the anchor loose via the deck cleat approach, I only need a windlass for lifting the last bit of chain, anchor and clinging mud. We have a salt water wash down pump, if needed, to rid the mud.

New Bern has a membership workshop available. For $10 an hour one can use the tools and facility.

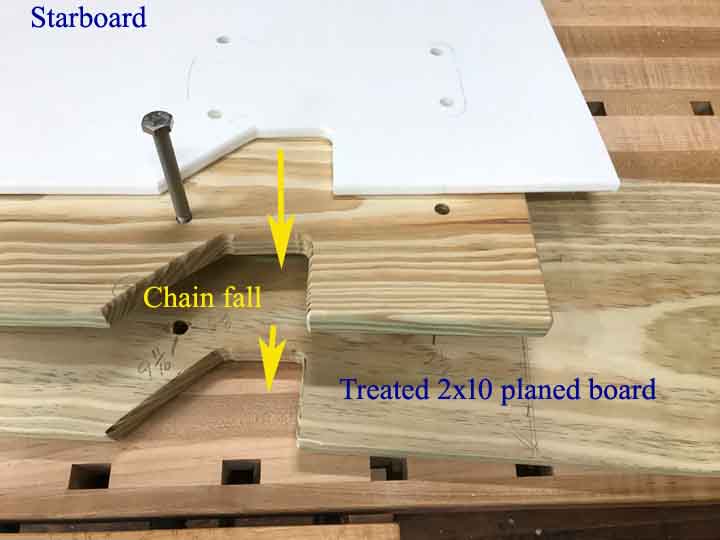

Having made a cardboard pattern for shaping the Starboard base, it was simply a matter of cutting and test fitting the material. “Measure twice and cut once.” Following that advice, required multiple trips to our Gemini catamaran to fit the three layers of material as the project evolved.

I had bought the straightest 2” by 10” by 10ft treaded pine board I could find. It dried for literally 2 months after purchase. The section which was to form the spacer and main attachment boards were planed down to 1” thickness to save weight.

The shops drill press was used to insure hole patterns aligned to the windlass base pattern.

Edges of the wood were rounded to minimize splinters.

The chain fall opening was cut for each of the three parts.

Large c-clamps (to the outer deck) held the attachment board in place within the anchor locker. Test fitting was performed and holes subsequently drilled which match the anchor cleat.

The system works well.

The story / blog of Yacht A Fun, a Gemini catamaran sailboat, traveling the ICW and east coast with insights to the extended cruising life. Lofrans Royal windlass